我们只做高品质的产品

公司以诚信、实力和产品质量获得业界的认可,欢迎各界朋友莅临参观,指导和业务洽谈

-

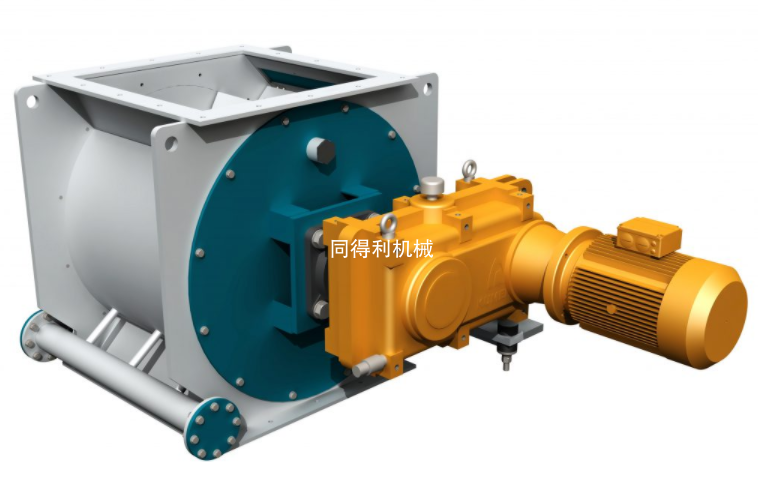

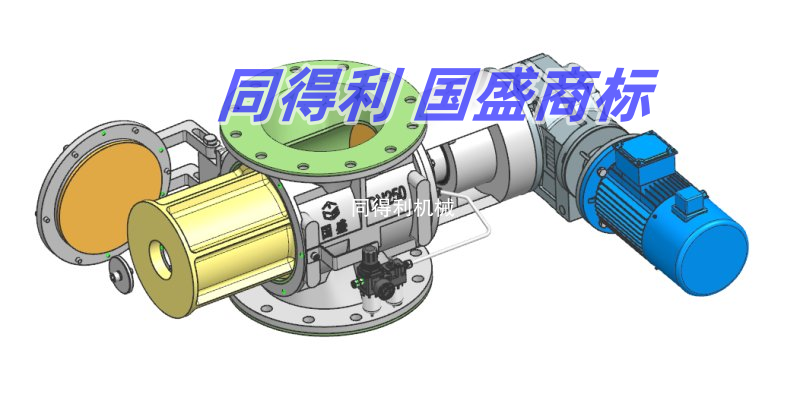

【对标-芬兰BMH旋转给料机】固体燃料处理/ 芬兰BMH旋转阀,BMH卸料阀,BMH旋转给料机,芬兰BMH旋转给料阀

产品介绍芬兰BMH Technology旋转给料机/旋转阀/卸料阀广泛应用在各种工艺中,用于给料,分配细料和多尘物料。通常是定制化设计以满足特定的应用和物料需求。旋转给料机将,例如SRF、生物质、煤炭或飞灰等送入发电锅炉,同时起到部分锁的作用,防止气体和火焰的回流。它们还可用作筒仓出口处的分配给料机,以防止物料不受控制地从筒仓中排出。 芬兰BMH Technology旋转给料机主要优势: 模块化坚固设计,标准组件, 运行稳定, 完全封闭防尘和安全结构, 易于安装和 维护需求小。 进口品牌价格贵,交期长怎么办?找国产替代,选大品牌-国盛商标常州同得利,专 利技术,匠心质造。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。 我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于锂电池、粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、塑料、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及管网正负压状态下的卸料。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询对标BMH旋转阀》 Finnish BMH Technology rotary feeders/rotary valves/discharge valves are widely used in various processes for feeding, distributing fine and dusty materials. It is usually customized design to meet specific application and material requirements. The rotary feeder feeds materials such as SRF, biomass, coal, or fly ash into the power generation boiler, while also serving as a partial lock to prevent gas and flame backflow. They can also be used as distribution feeders at the silo outlet to prevent uncontrolled discharge of materials from the silo. The main advantages of Finland BMH Technology rotary feeder are: Modular and robust design, standard components, Stable operation, Completely enclosed dust-proof and safe structure, Easy to install and Low maintenance requirements. What should we do if imported brands are expensive and have long delivery times? Find domestic alternatives, choose the big brand - Guosheng trademark Changzhou Tongdeli, patented technology, and craftsmanship.查看详情 +

-

【清洗型】水冷耐高温滑杆式旋转阀/ 清洗型旋转阀,滑杆式旋转阀,高温旋转阀,水冷型旋转阀

产品介绍【清洗型】水冷耐高温滑杆式旋转阀,此产品由本公司自主研发生产,其特点集聚一身:水冷式耐高温<1000℃,鹰嘴防卡防堵,滑杆式可清洗叶轮,高卫生标准。 快速清洗旋转阀制作精致、成功使用德、日技术制造之精华。产品拆装灵活、易于清洗。主要用于化工、制药、食品等行业高卫生标准的物料卸料及经常更换物料的场所工作。 滑杆式旋转阀可拆卸叶轮:便于快速拆卸清洗旋转阀的物料接触面。 驱动方式:链驱动/马达直连驱动。 动力配置:摆线针轮减速机,Y系列电机(可按客户指定动力配置) 滑杆式旋转阀/星型卸料阀:清洗前的拆卸。松开螺栓手柄,沿导柱将端盖轻轻拉至极限,抽出叶轮,双手握住叶轮两端抽颈取出。清洗后,装入叶轮(转动叶轮使花键齿合),推入端盖(转动活动轴柄使花键齿合),拧紧螺栓手柄。【电话/微信咨询:陈经理18068546632】 水冷耐高温旋转阀:适用于温度过高的物料,很好的降温。 阀体:采用整体浇铸于不锈钢全 面通水降温。 端盖采用全 面通水降温,避免轴承传递高温。 叶轮主轴采用全 面通水降温,避免高温形变,影响同心度。 我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于锂电池、粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、塑料、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及管网正负压状态下的卸料。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询水冷耐高温滑杆式旋转阀》 Sliding rod rotary valve/star discharge valve: disassembly before cleaning. Release the bolt handle, gently pull the end cover along the guide column to the limit, extract the impeller, and hold both ends of the impeller with both hands to remove the neck. After cleaning, install the impeller (rotate the impeller to engage the spline teeth), push in the end cover (rotate the movable shaft handle to engage the spline teeth), and tighten the bolt handle. Water cooled high-temperature resistant rotary valve: suitable for materials with excessively high temperatures, providing excellent cooling. Valve body: It is cast as a whole in stainless steel and fully cooled by water flow. The end cover adopts comprehensive water cooling to avoid bearing transmission of high temperature. The impeller spindle adopts comprehensive water cooling to avoid high-temperature deformation and affect concentricity. Our company specializes in the production of (B) GFY, YJD series air shut-off fans (air shut-off devices), star shaped unloaders, DS series electric air locks, DN type rotary valves, quick opening valves, cleaning valves, pneumatic rotary valves and other products. Widely used in equipment for industries such as lithium batteries, grain, feed, petrochemicals, pharmaceuticals, starch, oils and fats, chemical drying, plastics, dust removal, metallurgy, environmental protection, electronics, coal, construction, and power machinery. Used for unloading solid granules, powders, and ultrafine powders under pneumatic conveying and positive and negative pressure in pipeline networks.查看详情 +

-

【锂电卸料阀】聚氨酯卸料阀-防金属接触/ 锂电卸料阀,锂电旋转阀,聚氨酯卸料阀,聚氨酯旋转阀

产品介绍侧快拆卸料阀/星型旋转阀/关风机卸料器主要结构:外壳金属;物料接触部分:内衬聚氨酯、尼龙、四氟、陶瓷、特氟龙、钛合金、铝合金、不锈钢。 主要用于输送锂电池正极材料、磷酸铁锂、三元材料、化工、食品、制药等。 特点:物料粘接设备,可以快速清理,快速复位。 稳定性优于其他开拆式阀门,可原地抽出转子进行清洗。【电话/微信咨询:陈经理18068546632】 卸料阀内衬是指在阀门衬里加一层具有一定特性的防腐、耐磨材料进行衬里处理的技术。常见的衬里材料有陶瓷、特氟龙、尼龙、聚氨酯、聚四氟乙烯(PTFE)等。 内衬聚氨酯卸料阀的设计进一步增强了这种旋转卸料阀门的功能性和耐用性。聚氨酯作为一种耐磨、耐腐蚀、防金属接触的材料,能够有效地抵抗流体中的腐蚀性成分,保护阀门内部不受损害。同时,聚氨酯的耐磨性也延长了旋转阀门的使用寿命,减少了维护和更换的频率。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询锂电内衬聚氨酯卸料阀》 Side quick disassembly material valve/star shaped rotary valve/shut-off fan unloader main structure: metal shell; Material contact parts: lined with polyurethane, nylon, PTFE, ceramic, PTFE, titanium alloy, aluminum alloy, stainless steel. Mainly used for transporting positive electrode materials of lithium batteries, lithium iron phosphate, ternary materials, chemicals, food, pharmaceuticals, etc. Features: Material bonding equipment that can be quickly cleaned and reset. Stability is superior to other detachable valves, and the rotor can be removed in place for cleaning. Unloading valve lining refers to the technology of adding a layer of anti-corrosion and wear-resistant material with certain characteristics to the valve lining for lining treatment. Common lining materials include ceramics, PTFE, nylon, polyurethane, polytetrafluoroethylene (PTFE), etc. The design of the polyurethane lined discharge valve further enhances the functionality and durability of this rotary discharge valve. Polyurethane, as a wear-resistant, corrosion-resistant, and metal contact resistant material, can effectively resist corrosive components in fluids and protect the interior of valves from damage. Meanwhile, the wear resistance of polyurethane also extends the service life of rotary valves and reduces the frequency of maintenance and replacement.查看详情 +

-

【锂电旋转阀】DN200清洗型旋转阀-耐腐耐磨/ 锂电卸料阀,清洗型旋转阀,锂电旋转阀,耐磨旋转阀,耐腐蚀旋转阀,耐磨星型卸料器

产品介绍【锂电旋转阀】DN200清洗型旋转阀-耐腐蚀,耐磨,防金属接触本产品特性:特氟龙法兰+尼龙叶轮+侧快拆式+清洗型拆卸方法:用扳手松开开门端盖上的四个螺栓,把叶轮拉出清理。安装方法:把清理后的叶轮推进阀体内部,轻轻转动叶轮,使叶轮装进空心轴内部,确定安装好后,用扳手拧紧螺栓。旋转阀安装时应保证垂直、水平安装,请勿偏斜。使用前应检查电源正确接入,确保无误。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询锂电清洗型旋转阀》查看详情 +

-

【锂电/化工卸料阀】四氟卸料阀-防腐防粘附/ 四氟卸料器,四氟卸料阀,四氟旋转阀,内衬四氟卸料阀

产品介绍四氟星型卸料阀主要结构:外壳金属;物料接触部分:内衬四氟(也可尼龙、陶瓷、特氟龙、聚氨酯等)。主要用于输送锂电池正极材料、磷酸铁锂、三元材料、化工粉料等。特点:耐腐蚀、防粘、耐高温、耐磨、使用寿命长。内衬四氟卸料阀特点:1.防腐蚀作用:四氟内衬具有优异的耐腐蚀性能,能够抵抗酸、碱、盐和各种有机物的侵蚀,可以保护设备免受化学物质的腐蚀,延长设备的使用寿命。2.防粘附作用:四氟内衬表面具有良好的不粘附性,能够防止设备表面附着物的黏附,避免管道物料:粉体/颗粒料在长期运行过程中出现结垢、石灰积垢等现象,从而提高了设备的效率。3.减少摩擦作用:四氟内衬具有极低的摩擦系数,能够减少设备运行过程中的摩擦,降低能源损耗,提高了设备的使用寿命。4.耐高温性:四氟卸料阀放料阀具有出色的耐高温性能,能够在高温环境下保持稳定的工作状态。【电话/微信咨询:陈经理18068546632】四氟星型卸料阀适用于是0.8-3kg/cm²系统压力或压差。设置排气口(正压输送时选用)将叶轮旋转带出的气体通过排气口送至排期装置,提高填充效率。四氟卸料阀极小的间隙和特殊的密封装置保持设备的可靠运行。轴承外置式安装、经久耐用、性能优异。提供链驱动、直联驱动多种安装方式。【电话/微信咨询:陈经理18068546632】该型陶瓷卸料阀机组进出口安装尺寸一致,是根据不同的安装要求而专门设计的机型。箱体材质主要有:不锈钢、铝合金、钛合金等。 DN200四氟星型卸料阀 《扫二维码-添加 陈经理 微信-咨询四氟星型卸料阀》PTFE star shaped discharge valveMain structure: metal shell; Material contact part: lined with PTFE (also nylon, ceramic, PTFE, polyurethane, etc.).Mainly used for transporting lithium battery cathode materials, lithium iron phosphate, ternary materials, chemical powders, etc.Features: Corrosion resistance, anti sticking, high temperature resistance, wear resistance, long service life.Features of PTFE lined discharge valve:1. Anti corrosion effect: PTFE lining has excellent corrosion resistance, which can resist the erosion of acids, alkalis, salts, and various organic substances, protect equipment from chemical corrosion, and extend the service life of equipment.2. Anti adhesion effect: The surface of the PTFE lining has good non adhesion, which can prevent the adhesion of attachments on the equipment surface and avoid scaling and lime accumulation of pipeline materials such as powder/particle materials during long-term operation, thereby improving the efficiency of the equipment.3. Reduce friction: PTFE lining has an extremely low coefficient of friction, which can reduce friction during equipment operation, reduce energy loss, and improve the service life of equipment.4. High temperature resistance: The PTFE discharge valve has excellent high temperature resistance and can maintain a stable working state in high temperature environments.查看详情 +

-

【正压输送】风送滑杆式卸料阀/ 风送卸料阀,风送旋转阀,风送滑杆式卸料器,滑杆式旋转阀

产品介绍【风送滑杆式卸料阀】主要结构:外壳金属;物料接触部分:内衬陶瓷(也可碳化钨、尼龙、四氟、特氟龙、聚氨酯、合金、不锈钢等)。主要用于化工、食品、药材、锂电原料输送。针对物料粘接,风力直吹转子清理。快拆清理,快速复位。清洗前的拆卸。松开螺栓手柄,沿导柱将端盖轻轻拉至极限,抽出叶轮,双手握住叶轮两端抽颈取出。清洗后,装入叶轮(转动叶轮使花键齿合),推入端盖(转动活动轴柄使花键齿合),拧紧螺栓手柄。【电话/微信咨询:陈经理18068546632】轴承外置式:有效的防止粉尘侵入轴承,增大设备适应较高温度的使用范围。驱动方式:链驱动/马达直连驱动口。动力配置:摆线针轮减速机、Y系列电机(可按需方指定动力配置)。主要材料:不锈钢304-316、四氟、尼龙、钛合金、铝合金、各种合金等。【电话/微信咨询:陈经理 18068546632】我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于锂电池、粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、塑料、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及管网正负压状态下的卸料。 《扫二维码-添加 陈经理 微信-咨询风送滑杆式卸料阀》Wind driven sliding rod unloading valveMain structure: metal shell; Material contact part: lined with ceramic (also tungsten carbide, nylon, PTFE, PTFE, polyurethane, alloy, stainless steel, etc.).For material bonding, clean the rotor with direct wind blowing. Quick disassembly and cleaning, quick reset.Disassemble before cleaning. Release the bolt handle, gently pull the end cover along the guide column to the limit, extract the impeller, and hold both ends of the impeller with both hands to remove the neck. After cleaning, install the impeller (rotate the impeller to engage the spline teeth), push in the end cover (rotate the movable shaft handle to engage the spline teeth), and tighten the bolt handle.External bearing: effectively prevents dust from entering the bearing and increases the equipment's adaptability to higher temperatures.Drive mode: chain drive/motor directly connected to the drive port.Power configuration: Cycloid pinwheel reducer, Y series motor (power configuration can be specified by the demand).Main materials: stainless steel 304-316. PTFE, nylon, titanium alloy, aluminum alloy, various alloys, etc.查看详情 +

-

DN200特氟龙旋转阀【化工专用旋转阀】防腐蚀防粘接/ 特氟龙卸料阀,特氟龙星型卸料器,特氟龙旋转阀

产品介绍DN200特氟龙旋转阀【化工专用旋转阀】防腐蚀防粘接特氟龙旋转阀卸料阀的主要作用包括防腐、减少摩擦和化学侵蚀、提高耐化学性能、增强柔韧性、增加耐用性,并符合多种标准。减少摩擦和化学侵蚀:特氟龙内壁光滑,极大地减少了摩擦和化学侵蚀,易于清洗,不会集结细菌,易于使用蒸汽、消毒剂和清洁剂进行清洁。防腐蚀:特氟龙(PTFE)因其优良的化学稳定性,不受已知的酸、碱、盐、氧化剂的腐蚀,因此被广泛应用于防腐领域,如内衬四氟是一种经济适用的防腐工艺。防粘附性能好:特氟龙对粘附物质具有特殊的抗粘性能,可以避免流体因黏附而产生的结垢和堆积。本产品适用于易粘接物料、腐蚀性物料的卸料,多用于化工行业。如:石灰石粉料,氢氧化铝粉末,干燥硫酸镍干粉,化工粉料,硬脂酸盐产品,化工固体原料,硫酸铝粉末,小颗粒化工料。DN200 Teflon Rotary Valve [Chemical Special Rotary Valve] Anti corrosion and Anti adhesionThe main functions of the PTFE rotary valve discharge valve include anti-corrosion, reducing friction and chemical erosion, improving chemical resistance, enhancing flexibility, increasing durability, and complying with various standards.Reduce friction and chemical erosion: The PTFE inner wall is smooth, greatly reducing friction and chemical erosion, easy to clean, does not accumulate bacteria, and is easy to clean with steam, disinfectants, and cleaning agents. Corrosion prevention: Teflon (PTFE) is widely used in the field of corrosion prevention due to its excellent chemical stability and resistance to known acids, bases, salts, and oxidants. For example, PTFE lining is an economical and applicable corrosion prevention process.Good anti adhesion performance: Teflon has special anti adhesion properties for adhesive substances, which can prevent fluid scaling and accumulation caused by adhesion.查看详情 +

-

耐高温旋转阀<1000℃/ 耐高温旋转阀,高温卸料阀

产品介绍ZGS耐高温系列旋转阀卸料阀,主要用于锅炉、火力发电等行业,本产品精选耐高温轴承,箱体叶轮轴承座采用循环水冷却,能承受小于1000度高温。 本系列产品也可根据用户特殊要求定制技术参数。【电话/微信咨询:陈经理18068546632】 我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及官网正负压状态下的卸料。 《扫二维码-添加 陈经理 微信-咨询产品/报价》 The ZGS high-temperature resistant series rotary valve discharge valve is mainly used in industries such as boilers and thermal power generation. This product selects high-temperature resistant bearings, and the impeller bearing seat of the casing is cooled by circulating water, which can withstand temperatures below 1000 degrees Celsius. This series of products can also customize technical parameters according to special user requirements. Our company specializes in the production of (B) GFY, YJD series shut-off fans (shut-off fans), star shaped unloaders, DS series electric air locks, DN type rotary valves, quick opening valves, cleaning valves, pneumatic rotary valves, and other products. Widely used in industries such as grain, feed, petrochemicals, pharmaceuticals, starch, fats, chemical drying, dust removal, metallurgy, environmental protection, electronics, coal, construction, and power machinery. Used for unloading solid particles, powders, and ultrafine powders under pneumatic conveying and positive and negative pressure on the official website.查看详情 +

-

衬尼龙快拆旋转卸料阀/ 快拆清洗旋转阀,尼龙卸料阀,尼龙星型阀

产品介绍衬尼龙快拆旋转卸料阀采用加厚叶轮设计,与壳体配合间隙小,结构精密,使用过程中不易漏风不易漏料,防堵耐用。 密封优越,用感无忧:结构稳定,密封性能良好。可用于粉料、小颗粒物料,在正负极压差吸送过程中将物料分离排出。 适用于锂电正极材料输送,高镍三元材料,磷酸铁锂。阀体、端盖外表面采用304.物料接触内衬尼龙工艺等。都可以满足工况耐磨,耐温尤为突出。【电话/微信咨询:陈经理18068546632】 此产品由本公司自主研制,适用于不可接触金属物料的卸料。箱体、叶轮以及端盖,都采用整块尼龙铣削加工,结构牢靠,运行无噪音,相较于陶瓷阀,可以节省成本,是锂电行业新宠。 衬尼龙快拆旋转卸料阀主要结构:壳体、叶轮、端盖,采用改性尼龙。 主要用于输送电池正极材料、磷酸铁锂、三元材料等。【电话/微信咨询:陈经理18068546632】 特点:改性尼龙比普通尼龙更耐磨,耐高温。 常州同得利技术研发于2016年,批量生产于2018年,2020年更新第4代尼龙星型阀,目前有尼龙星型阀发明专 利。 《扫二维码-添加 陈经理 微信-咨询产品或定制》 The nylon lined quick release rotary discharge valve adopts a thickened impeller design, with small clearance with the shell, precise structure, and is not prone to air leakage or material leakage during use, making it resistant to blockage and durable. Superior sealing and worry free use: stable structure and good sealing performance. Can be used for powder and small particle materials, to separate and discharge materials during the positive and negative pressure difference suction process. Suitable for transporting lithium battery cathode materials, high nickel ternary materials, and lithium iron phosphate. The outer surface of the valve body and end cover adopts 304 material contact lining nylon technology, etc. Both can meet the wear resistance requirements of working conditions, with outstanding temperature resistance. This product is independently developed by our company and is suitable for unloading non-contact metal materials. The casing, impeller, and end cover are all processed using a single piece of nylon milling, with a reliable structure and noiseless operation. Compared to ceramic valves, they can save costs and are a new favorite in the lithium battery industry. The main structure of the nylon lined quick release rotary discharge valve is a shell, impeller, and end cover, which are made of modified nylon. Mainly used for transporting battery cathode materials, lithium iron phosphate, ternary materials, etc. Features: Modified nylon is more wear-resistant and heat-resistant than ordinary nylon. Changzhou Tongdeli Technology was developed in 2016. mass-produced in 2018. and updated its fourth generation nylon star valve in 2020. Currently, it has a nylon star valve invention patent.查看详情 +

-

不锈钢喷涂特氟龙卸料阀/