我们只做高品质的产品

公司以诚信、实力和产品质量获得业界的认可,欢迎各界朋友莅临参观,指导和业务洽谈

-

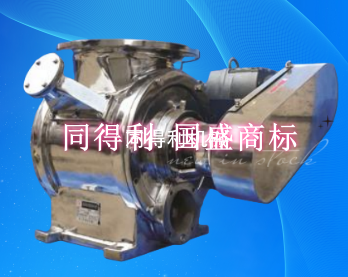

【锂电/化工卸料阀】陶瓷星型卸料阀-高温防腐防金属接触/ 陶瓷旋转阀,陶瓷星型卸料器,陶瓷旋转卸料阀

产品介绍星型卸料器用于安装在负压下工作的卸料器的排料口处,上部接受卸料器排出的物料,依靠旋转的叶轮起着输送物料的作用,又担负着密封的作用,防止气力输送过程中从排料口吸入空气,卸料器的正常排料做为一种特殊的卸料装备,在清洁和清洗工作中起到了很大的作用。The star shaped unloader is used to be installed at the discharge port of the unloader working under negative pressure. The upper part receives the material discharged by the unloader, and relies on the rotating impeller to transport the material and also plays a sealing role to prevent air from being sucked in from the discharge port during pneumatic conveying. The normal discharge of the unloader, as a special unloading equipment, plays a great role in cleaning and washing work.锂电/化工卸料阀-陶瓷卸料阀由本公司自主研制,已取得多项国家专 利。本品适用于不可接触金属物料,多用于锂电正极原料的生产制作。陶瓷阀的优点是超强耐磨,而且不会对锂电材料造成污染,是新能源大开发进程中一大助力。陶瓷卸料阀类型:滑杆式/侧快拆/耐高压/耐高温/锁风式/风送滑杆式/防卡型卸料阀(总有一款适合您的需求)【电话/微信咨询:陈经理18068546632】陶瓷星型卸料阀主要结构:外壳金属;物料接触部分:内衬陶瓷(也可尼龙、四氟、特氟龙、聚氨酯等)。陶瓷星型卸料阀主要用于输送锂电池正极材料,负极材料,磷酸铁锂,三元材料等物料的输送和卸料,可以提高生产效率,保证物料的质量的和稳定性,同时满足环保和安全的要求。陶瓷星型卸料阀特点:耐高温、耐磨、使用寿命长。陶瓷星型卸料阀技术研发于2015年,批量生产于2017年,2020年更新第3代陶瓷星型旋转阀,目前有陶瓷星型旋转阀专 利。我们购买星型旋转卸料阀输送物料时,如何才能选择合适的厂家?选择实力强的厂家,一般来说旋转卸料阀厂家可以见证产品的质量,实力强的厂家可为客户提供更好的产品质量和服务。要看厂家的实力、信誉、规模。同得利秉承以下服务承诺:服务目标:服务质量赢得用户满意。严格控制对产品性能的检测,待产品被确认合格后再出厂发货。提供的产品符合报价文件承诺和所签合同规定的技术要求。物美价廉,具有输送系统完全密闭,可以避免输送物料的受潮、污损或混入异物等优势。常用于锂电/化工/药材/食品/塑料/钢厂/电厂/矿山/水泥/环保等行业。【电话/微信咨询:陈经理18068546632】全新的铸造方法用于改善外表面光洁度和铸造完整性,阀体外壳强度更高。 《扫二维码-添加 陈经理 微信-咨询陶瓷星型卸料阀》Tongdeli adheres to the following service commitments:Service objective: To achieve customer satisfaction through high-quality service.Strictly control the testing of product performance, and only ship the product after it is confirmed to be qualified.The products provided meet the technical requirements as promised in the quotation documents and as stipulated in the signed contract.Affordable and cost-effective, with a completely sealed conveying system that can prevent moisture, dirt, or foreign matter from entering the conveyed material. Commonly used in industries such as lithium batteries, chemicals, medicinal materials, food, plastics, steel mills, power plants, mines, cement, and environmental protection.The new casting method is used to improve the surface smoothness and casting integrity, resulting in higher strength of the valve body shell.查看详情 +

-

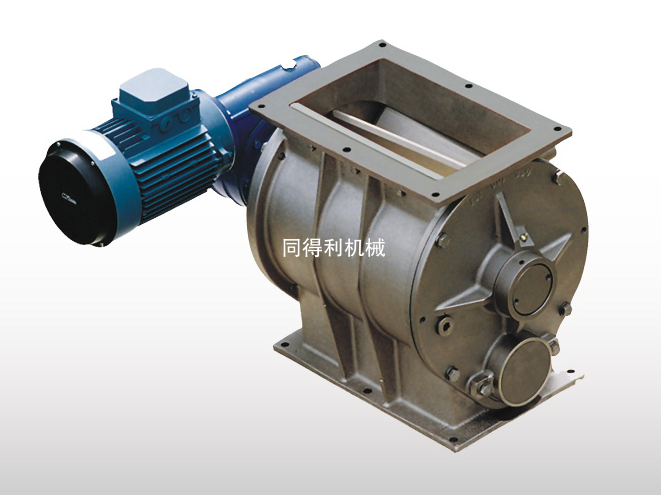

【对标进口品牌】刮板式旋转阀/ 刮板卸料阀,刮板式旋转阀,刮板卸料器

产品介绍刮板式旋转阀主要用于钢厂、电厂、水泥、矿山原料输送。刮板式旋转阀适用于具有吸湿性和物料架桥结块或带有静电吸附性的粉粒物料。阀体下部的旋转刮板自动将附在转子料斗内的物料刮除。刮板旋转阀阀体上开有清理口便于定期清除内部的物料,设备带扭力保护器。提供链驱动、马达直连驱动。【电话/微信咨询:陈经理18068546632】刮板旋转阀常见材质:碳钢、不锈钢系列、铝合金、钛合金、陶瓷系列等。按客户需求定制。 《扫二维码-添加 陈经理 微信-咨询产品》Scraper type rotary valves are mainly used for conveying raw materials in steel mills, power plants, cement, and mines.Scraper type rotary valve is suitable for powder materials with hygroscopicity, bridging and agglomeration of materials, or electrostatic adsorption.The rotating scraper at the bottom of the valve body automatically scrapes off the material attached to the rotor hopper.The scraper rotary valve body has a cleaning port for regular removal of internal materials, and the equipment is equipped with a torque protector.Provide chain drive and motor direct drive.Common materials for scraper rotary valves include carbon steel, stainless steel series, etc. Customize according to customer needs.查看详情 +

-

风送式旋转卸料阀/ 风送旋转阀,风送卸料阀

产品介绍风送式旋转卸料阀压力范围:2kg/cm²系统压力或压差。 增大入口/出口:正方形,没有截面尺寸对料流的限 制从而可达高产量。 普通型:结构紧凑,占用空间小。 轴承外置式:有效的防止粉尘侵入轴承,增大设备适应较高温度的使用范围。 驱动方式:链驱动/马达直联驱动。 动力配置:摆线针轮减速机、Y系列电机(可按客户指定动力配置)。 材质选项:钛合金、铝合金、陶瓷、不锈钢、碳钢等。 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粉料、超微粉体等。 Pressure range of pneumatic rotary discharge valve: 2kg/cm ² System pressure or differential pressure. Increase the inlet/outlet: square, with no restrictions on material flow due to cross-sectional size, achieving high production. Normal type: compact structure, occupying small space. External bearing type: effectively prevents dust from entering the bearing, increasing the equipment's adaptability to higher temperature usage range. Drive mode: chain drive/motor direct drive. Power configuration: cycloidal pinwheel reducer, Y-series motor (can be configured according to customer specifications). Material options: titanium alloy, aluminum alloy, ceramic, stainless steel, carbon steel, etc. Changzhou Tongdeli Machinery Factory has many years of experience in research and development, production, and customization of discharge valve rotary valves, adhering to the principle of quality first and customer first. Our rotary valve can handle various types of particles, flakes, blocks, powders, and ultrafine powders in industries such as lithium batteries, steel mills, power plants, cement, mines, environmental protection, plastics, chemicals, food, and pharmaceuticals.查看详情 +

-

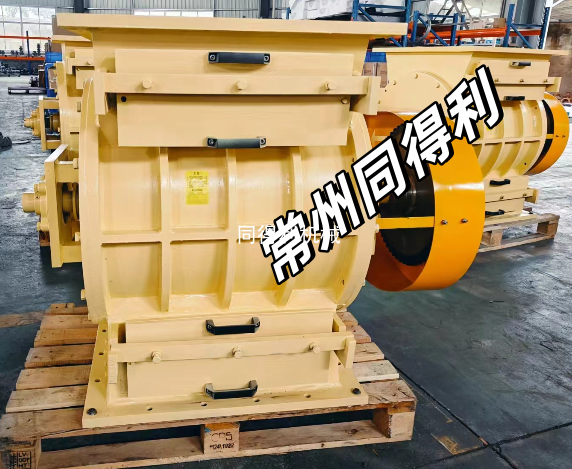

干熄焦旋转密封阀生产厂家/ 干熄焦旋转密封阀,干熄焦旋转阀,旋转排出阀,干熄焦密封旋转阀

产品介绍常州同得利机械厂与多家大型、中型钢铁公司的焦化厂合作开发研制了国产的干熄焦旋转密封阀,获得用户的好评。 干熄焦旋转密封阀(又称旋转排出阀、格式密封阀)是焦化厂干熄焦工程中的关键设备,安装在干熄炉底部,入料口与振动给料器连接、出料口与排焦溜槽相连接。其作用是把振动给料器定量排出地焦炭在密闭状态下连续排出。既能连续定量地排料,又具有良好的密封性及耐磨性。可以有效地控制干熄炉内的循环气体和粉尘的外泄,稳定干熄炉内循环气体的压力,是现代先进干熄焦工艺必选的关键设备。【电话/微信咨询:陈经理18068546632】干熄焦旋转密封阀结构特点: 旋转密封阀安装于干熄焦装置的zui下端出口处。主要由阀体、转子、密封副、下料槽、机架、台车、驱动装置和自动给脂装置等组成。功能是保证连续定量排焦并同时将系统内外分隔,稳定干熄炉系统压力。 旋转密封阀工作原理,旋转过程中,焦炭经各隔仓由上至下均匀排出,调整料仓的大小及转子的转速可适应不同料流量。为减少干熄炉内气体介质外漏,需控制转子刃与机体内壁的间隙,间隙越小,干熄炉内气体介质外漏量也就越小。转子端面密封采用金属硬密封结构。密封副为一组金属圆环,由弹簧压紧并能自动补偿间隙误差。为防止粉尘进入,此处设计有气体辅助密封,可保证端面密封装置正常运行。 该设备的密封副为多瓣环形结构,系软硬密封结合的形式,并采用弹簧辅助压紧,能够在运转过程中进行误差间隙自动补偿,保证密封性能。密封副之间由自动给脂装置定量给脂保证润滑,zui大限度地减小了磨损。并在阀体两侧轴承箱内通入高于干熄焦塔内压力的氮气或空气辅助密封,使干熄炉内高温(约200V)含尘气体不能进入轴承箱,改善了轴承和密封环的工作环境,能够有效地防止轴承温升超高,减少密封环磨损。 为满足连续密闭排焦功能,干熄焦旋转密封阀转子内部为12个叶片,转子两端支撑在阀体轴承箱内,为防止焦粉进入轴承箱,转子及阀体相应部位设置软硬密封机构,形成承料部位与轴承箱隔离空腔,并在此部位通入氮气吹扫、冷却,转子驱动轴端与行星摆线针轮减速机连接;阀体上口内设弹簧仓,能有效防止卡料,阀体下口与下料槽相连;下料槽设有积窝,可存积焦炭,使焦炭在排出过程形成料磨料,使落料尽量不接触机体,zui大限度地减小磨耗,以保护基体钢结构。 干熄焦旋转密封阀驱动方式有两种:一种行星减速机通过联轴器与转子相连直接驱动转子旋转(见图4);另一种行星减速机通过链传动带动转子旋转。减速机电动机可采用变频调速(根据客户需求),调速范围2~6r/rain,实现设备软起动、过载保护等功能,减缓冲击。链传动旋转密封阀设有断链检测装置,当链条断裂时,能自动报警。 阀体、转子、下料槽和驱动装置组装成一体置于台车上。台车下设有4个车轮,整体设备安装和拆卸非常方便;设备就位后用止挡座固定在工位上。检修时沿地面铺设的轨道推出至检修平台。此外为安装方便在旋转密封阀的上下断面还设置了补偿器。在轴承及阀体与转子密封部位设有多个润滑点,自动润滑装置定时定量提供润滑脂。 2.干熄焦密封旋转阀材料选择:【电话/微信咨询:陈经理18068546632】 由于旋转密封阀特殊的工作环境,材料选择直接关系到旋转密封阀产品能否长期可靠运行。在排焦工作状态,焦炭对机体和转子造成强烈磨损,需安装高耐磨衬板保护。干熄焦旋转密封阀内腔与焦炭接触面均装有耐磨衬板。不同部位材料也不同:转子刃口采用特种高硬度、高耐磨、高碳高钒高速工具钢;转子行星格腔表面、阀体内表面及下料槽内表面均采用高耐磨板t阀门入料采用高铬铸铁。密封副为高耐磨轴承合金和耐磨钢软硬搭配;阀门主体采用低碳合金结构钢。 常州同得利引进国内外先进的设计制造技术,专注定制-研发-生产旋转阀,关风机,卸料阀,锁气阀。 本厂地处经济发达的龙城常州,交通便利,沪宁高速、沿江高速、锡宜高速、新长铁路,为本厂制造了得天独厚的地理优势。 本厂坚持"质量过硬,用户满意"的宗旨,愿与您携手共进,诚信合作,互惠互利,共同发展。 《扫二维码-添加 陈经理 微信-咨询产品》 Changzhou Tongdeli Machinery Factory has collaborated with coking plants of multiple large and medium-sized steel companies to develop domestically produced rotary sealing valves for dry quenching coke, which have received high praise from users. The rotary sealing valve (also known as the rotary discharge valve or format sealing valve) is a key equipment in the dry quenching project of a coking plant. It is installed at the bottom of the dry quenching furnace, and the feeding port is connected to the vibrating feeder, while the discharging port is connected to the coke discharge chute. Its function is to quantitatively discharge the coke from the vibrating feeder and continuously discharge it in a closed state. It can continuously and quantitatively discharge materials, and has good sealing and wear resistance. It can effectively control the leakage of circulating gas and dust inside the dry quenching furnace, stabilize the pressure of circulating gas inside the dry quenching furnace, and is a key equipment that must be selected for modern advanced dry quenching technology.查看详情 +

-

陶瓷卸料阀/ 陶瓷卸料阀,星型卸料阀,陶瓷旋转卸料阀

产品介绍陶瓷卸料阀系列:·适用于是0.8-3kg/cm²系统压力或压差。·设置排气口(正压输送时选用)将叶轮旋转带出的气体通过排气口送至排期装置,提高填充效率。·极小的间隙和特殊的密封装置保持设备的可靠运行。·轴承外置式安装、经久耐用、性能优异。·提供链驱动、直联驱动多种安装方式。·该型陶瓷卸料阀机组进出口安装尺寸一致,是根据不同的安装要求而专门设计的机型。·箱体材质主要有:不锈钢、铝合金·内衬材质主要有:陶瓷、四氟、PVC·内喷涂材质有:陶瓷粉、碳化钨、特氟龙。【电话/微信咨询:陈经理18068546632】 【电话/微信咨询:陈经理18068546632】 Ceramic discharge valve series: ·Applicable to 0.8-3kg/cm ² System pressure or differential pressure. ·Set up an exhaust port (selected for positive pressure conveying) to send the gas carried out by the impeller rotation to the scheduling device through the exhaust port, improving the filling efficiency. ·The minimal gap and special sealing device ensure the reliable operation of the equipment. ·External installation of bearings, durable, and excellent performance. ·Provide multiple installation methods for chain drive and direct drive. ·This type of ceramic discharge valve unit has consistent inlet and outlet installation dimensions and is specially designed according to different installation requirements. ·The main materials of the box include stainless steel and aluminum alloy ·The main lining materials include ceramics, PTFE, and PVC ·The internal spraying materials include: ceramic powder, tungsten carbide, and PTFE 《扫二维码-添加 陈经理 微信-咨询产品》查看详情 +

-

特氟龙涂层卸料阀/

-

【对标-意大利威埃姆WAMGROUP】旋转阀&螺旋输送机/ 威埃姆旋转阀,WAMGROUP旋转阀,威埃姆螺旋输送机,意大利WAMGROUP

产品介绍常州同得利拥有多年的研发生产/定制旋转阀的经验,匠心质造,口碑好,专 业替代进口意大利威埃姆WAMGROUP旋转阀。旋转阀可分为:普通型,耐高压型,外装耐高温耐高压型,快速清洗型,定量型。 【同得利】食品/制药/化工/塑料原料输送旋转阀常见分类有:风送滑杆旋转阀,侧快拆旋转阀,滑杆式旋转阀,风送式旋转阀,防卡式旋转阀,耐压型旋转阀,哈氏合金旋转阀,钛合金旋转阀,合金旋转阀,铝合金旋转阀,陶瓷旋转阀,陶瓷氧化铝旋转阀,四氟旋转阀,不锈钢旋转阀。 钢厂/电厂/水泥/环保/矿山原料输送旋转阀常见分类有:偏置式旋转阀,刮板式旋转阀,耐高温旋转阀,锁风旋转阀,双叶轮旋转阀,刚性旋转阀,螺旋输送机:1、破拱.锁气.防冲料.组合螺旋送料机;2、双向螺旋输送机;3、精准喂料螺旋送料机;4、子母螺旋输送机;5、提升螺旋输送;6、双螺旋输送机;7、滑杆快拆螺旋送料机;8、高温螺旋输送机;9、水冷式螺旋输送机。 进口品牌意大利威埃姆WAMGROUP 价格贵,交期长怎么办?WAMGROUP威埃姆旋转阀系列:REC,RES,RV,RVR,RVC,RVS,RWN。WAMGROUP威埃姆螺旋输送机系列:CX,CAO,CA,MSC,CLO,CLOS,UC,BU,MT,HT,CMC,TU,THF,TCF,ES,TXF,TX,TE,TP,SU,SPL,SVE,PR,ESV,VE,SSC。找国产替代,选大品牌-国盛商标常州同得利,专 利技术,匠心质造。 【同得利】可以替代全球一线品牌旋转阀:【电话/微信咨询:陈经理18068546632】 威埃姆滑杆式旋转阀:REC - RES系列: SlideOut Rotary Valves are engineered with a continuously revolving rotor featuring two compartments, both of which are filled with material simultaneously via the top inlet. The valves come in two distinct versions: REC and RES. Standard rotor with integrated shaft Drive unit mounted on rotor shaft Air-purged shaft seal Feed rate: 5-10-20-35 litres per revolution (0.17-0.35-0.70-1.2 cu ft/rev) for 2”, 3”, 4” and 5” conveying pipes Working temperature: -40 ~ 150 °C (-40 ~ 302 °F) Working pressure: up to 1 bar (14 psi) WAMGROUP威埃姆直通型旋转阀 RV - RVR系列: RV旋转阀为多用型,用于控制来自料仓、料斗、气力输送系统、过滤器布袋或旋风分离器的粉末或颗粒状物料的卸料及喂料。【替代方案--电话/微信咨询:陈经理18068546632】 进料速度:2.2~19.5 l/转(0.08 ~ 0.7 cu ft 每转) 阀体采用铸铁或304/316不锈钢(仅 限RV) 对于粘性物料或进料速率降低的情况,采用隔间插片 油密封、气密封或空气清洗式密封 带固定齿轮箱的直接驱动 带变速箱的直接驱动 带链传动的同轴驱动 WAMGROUP威埃姆直通型旋转阀 RVC系列: RVC直通型旋转阀的组成为一个铸铁或不锈钢的筒形外壳,一个水平安装的转轴,轴上有一定数量截面形状为V形的隔板,一个驱动装置,以及有一层保护套的两轴端。【替代方案--电话/微信咨询:陈经理18068546632】 喂料速度:5-9-14-20-38升/转(0.17-0.3-0.5-0.7-1.3cu ft/转) 定速转轴速度:10/20/30 r.p.m 变速转轴速度;4-22 r.p.m 外壳:铸铁或304/316不锈钢 轴上的密封件:耐高温 驱动:直接驱动,可变速齿轮箱电机驱动;用链传动装置来进行驱动;无驱动器。 带风扇冷却装置的电机 电机绕组控温装置 叶片上有刮刀 WAMGROUP威埃姆气力输送旋转阀 RVS系列: RVS气力输送旋转阀的组件有:一个铸铁或不锈钢的筒形外壳;一根水平放置的转轴,轴上有一定数量、截面形状为V型的倾斜隔间;一个驱动装置及有一层保护层的每个端部。【替代方案--电话/微信咨询:陈经理18068546632】 喂料速度:5-9-14-20-38升/转(0.17-0.3-0.5-0.7-1.3cu ft/转) 转轴:转轴上配有斜面叶片,叶片上带有刮刀(Viton®、Vulkolan、Teflon®) 定速转轴速度:10 / 20 / 30 r.p.m. 变速转轴速度:4 – 22 r.p.m. 外壳:铸铁或304/316不锈钢 轴密封件:润滑油脂,气体/净化氮气密封,或耐高温 带风扇冷却装置的电机 电机电热调节器 叶片上有刮刀 WAMGROUP威埃姆用于木屑颗粒的直通型旋转阀 RWN系列: RWN旋转阀是控制木屑或来自碎煤机,料仓和料斗的木屑的卸料和进料的理想解决方案。RWN旋转阀专为从料仓、料斗、气力输送系统、布袋除尘器,或旋流器定量排放和填充木屑颗粒或碎屑而设计。旋转刀具形状和进料口处的切割阀板,保证所有出现的生物燃料混合物将被切碎。 用于3种旋转速度的不同驱动(10. 20 或 30 r.p.m). WAM法兰标准件,保证与其他WAM设备的兼容性 结构紧凑,经久耐用 装在进料口的HARDOX阀板切割木屑,避免阻塞 用于特殊型号的操作温度:-20℃~150℃(-4℉~300℉) 轴封采用油脂、空气或吹气密封 带齿轮电机的直接驱动【替代方案--电话/微信咨询:陈经理18068546632】 WAMGROUP威埃姆螺旋输送机/喂料机: WAMGROUP威埃姆旋转阀,螺旋输送机均可替代: 【替代方案--电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询替代方案》查看详情 +

-

【链驱动】刚性旋转阀-钢厂/电厂/矿山/水泥/ 钢厂旋转阀,电厂旋转阀,矿山旋转阀,刚性旋转阀,刚性卸料阀

产品介绍刚性旋转阀/卸料阀/旋转卸料器/旋转供料器常用于难处理的物料, 适用于粉料、颗粒和磨料(坚硬物料、块状物料、高温物料)的旋转卸料阀。大型号旋转阀,为高流量设计,适用于重负荷和严苛的应用环境,压力可达2 bar(g) [20 psi(g)]可抵抗严苛的冲击力,承受高温达300℃,压力范围:1.4 巴(g) [20 psi(g)]轴封:聚四氟乙烯复合密封,空气吹扫。外侧轴承:通过密封和物料掉落口将物料和轴承隔开。 刚性旋转阀主要用于钢厂、电厂、水泥、矿山等行业。叶轮稳定性好、圆滑过度、无夹角、扭矩更大。【电话/微信咨询:陈经理18068546632】 1、结构紧凑:采用行星转动原理、纯铜电机,输入输出在同一轴线上,而且有与电机直联一体的独特性,体积小,重量轻,因而结构紧凑造型美观新样。 2、耐磨性高:运行可靠平稳,噪音低,故障少,寿命长,耐磨性高。 3、过载能力强:卸料器具有过载能力强,耐冲击惯性力矩小,适用于启动频繁和正反转。 4、使用寿命长:轴承、齿箱、远离阀体避免高温灰尘的影响,前后密封性能好,防止灰尘外泄,延长机动件,润滑系统的使用寿命。 5、支持定制/替代进口品牌:用户如有特殊规格要求,可以按照客户要求定做。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询刚性旋转阀》 Rigid rotary valves/discharge valves/rotary unloaders/rotary feeders are commonly used for difficult to handle materials, suitable for rotary discharge valves of powders, particles, and abrasives (hard materials, block materials, high-temperature materials). Large rotary valve, designed for high flow, suitable for heavy loads and harsh application environments, with a pressure of up to 2 bar (g) [20 psi (g)], can resist harsh impact forces, withstand high temperatures up to 300 ℃, pressure range: 1.4 bar (g) [20 psi (g)], shaft seal: PTFE composite seal, air blowing. Outer bearings: Separate materials and bearings through seals and material drop ports. Rigid rotary valves are mainly used in industries such as steel mills, power plants, cement, and mining. The impeller has good stability, smooth transition, no angle, and greater torque. 1. Compact structure: Adopting the principle of planetary rotation and a pure copper motor, the input and output are on the same axis, and it has the unique feature of being directly connected to the motor. It is small in size and light in weight, resulting in a compact structure and beautiful appearance. 2. High wear resistance: reliable and stable operation, low noise, few faults, long service life, high wear resistance. 3. Strong overload capacity: The unloader has strong overload capacity, low impact resistance inertia moment, and is suitable for frequent starting and forward and reverse rotation. 4. Long service life: bearings, gearboxes, and valves are kept away from the valve body to avoid the influence of high temperature dust. The front and rear sealing performance is good, preventing dust leakage and extending the service life of motor components and lubrication systems. 5. Support customization/substitution of imported brands: If users have special specifications requirements, they can customize according to their needs.查看详情 +

-

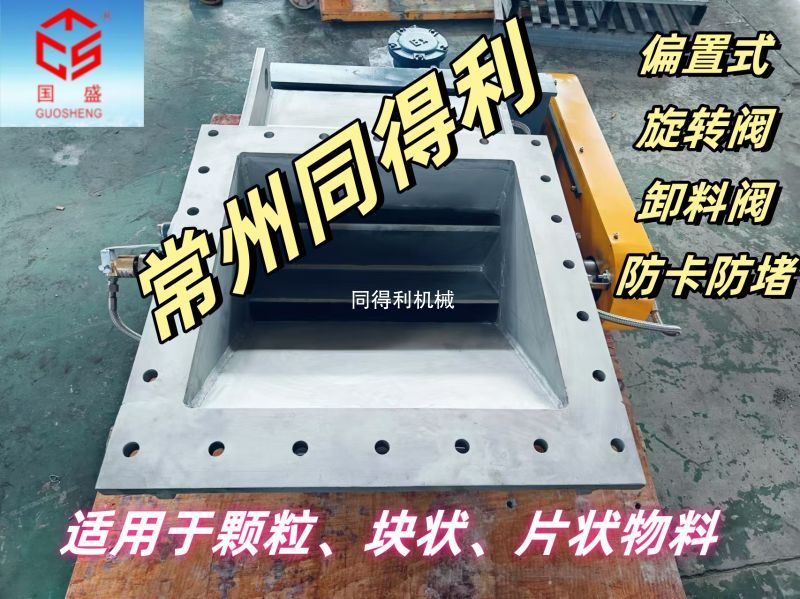

【钢厂|电厂|水泥|矿山】偏置式旋转阀-防卡防堵/ 钢厂旋转阀,电厂旋转阀,水泥旋转阀,矿山旋转阀,偏置旋转阀

产品介绍偏置式旋转阀主要用于钢厂、电厂、水泥、矿山等行业原料输送卸料。 适用于块状、颗料、片状物料,起到很好的防卡防堵作用。 防切料入口设计:即便上游充满物料也可安全启动。 偏置式进出料口设计:减少了物料的破碎与损坏。 全新的铸造方法用于改善外表面光洁度和铸造完整性,阀体外壳强度更高。【电话/微信咨询:陈经理18068546632】 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。 《扫二维码-添加 陈经理 微信-咨询偏置式旋转阀》 Offset rotary valves are mainly used for raw material transportation and unloading in industries such as steel mills, power plants, cement, and mines. Suitable for block, particle, and sheet materials, it has a good anti jamming and anti blocking effect. Anti cutting material inlet design: Even if the upstream is filled with materials, it can be safely started. Offset inlet and outlet design: reduces material breakage and damage. The new casting method is used to improve the surface smoothness and casting integrity, resulting in higher strength of the valve body shell. Changzhou Tongdeli Machinery Factory has many years of experience in research and development, production/customization of discharge valve rotary valves, adhering to the principle of quality first and customer first. Our rotary valves are capable of handling various types of particles, flakes, blocks, adhesives, powders, ultrafine powders, etc. in industries such as lithium batteries, steel mills, power plants, cement, mining, environmental protection, plastics, chemical, food, and pharmaceuticals.查看详情 +

-

不锈钢防卡旋转阀-颗粒/块状/片状料/ 不锈钢旋转阀,防卡旋转阀,防卡卸料阀,防卡星型卸料器

产品介绍不锈钢防卡旋转阀主要用于塑料、食品、化工、锂电、矿山、环保行业原料输送。 针对颗粒、片状、块状物料,实现不卡料、不堵料。 防卡型旋转阀主要材质:不锈钢304-310、铝合金、钛合金、陶瓷系列等。 压力:2kg/cm²系统压力或压差。 增大入口/出口:正方形和圆形。 轴承外置式:有效的防止粉尘侵入轴承,增大设备适应较高温度的使用范围。 驱动方式:链驱动/马达直连驱动口。 动力配置:摆线针轮减速机、Y系列电机(可按需方指定动力配置),排气口增压输送时将叶轮旋转带出的高压气体通过排气口送至排气装置,提高填充效率。【电话/微信咨询:陈经理18068546632】 旋转阀气密封装置主要用于在气力输出系统中,特别是在需要处理粉尘和小颗粒物料的场合。工作原理依赖于气体密封技术,通过保持一定的气源压力,通常高于管道内压力0.1个大气压,从而在卸料阀内部形成正负压差,确保充气的压力大于内部物料的压力,从而实现有效的密封。这种设计不仅提高了卸料阀的可靠性,还能有效防止物料在输送过程中的泄漏,确保系统的正常运行。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询不锈钢防卡旋转阀》 Stainless steel anti seize rotary valves are mainly used for raw material transportation in the plastic, food, chemical, lithium battery, mining, and environmental protection industries. For granular, flake, and block materials, achieve no material jamming or blockage. The main materials of anti jamming rotary valve include stainless steel 304-310. aluminum alloy, titanium alloy, ceramic series, etc. Pressure: 2kg/cm ² system pressure or pressure difference. Increase entrance/exit: square and circular. External bearing: effectively prevents dust from entering the bearing and increases the equipment's adaptability to higher temperatures. Drive mode: chain drive/motor directly connected to the drive port. Power configuration: Cycloid pinwheel reducer, Y-series motor (can be configured according to the power requirements specified by the demand). When the exhaust port is pressurized and transported, the high-pressure gas carried out by the impeller rotation is sent to the exhaust device through the exhaust port to improve the filling efficiency. The rotary valve air seal device is mainly used in pneumatic output systems, especially in situations where dust and small particle materials need to be processed. The working principle relies on gas sealing technology. By maintaining a certain gas source pressure, usually 0.1 atmospheres higher than the pressure inside the pipeline, a positive and negative pressure difference is formed inside the discharge valve to ensure that the inflation pressure is greater than the pressure of the internal material, thus achieving effective sealing. This design not only improves the reliability of the discharge valve, but also effectively prevents material leakage during transportation, ensuring the normal operation of the system.查看详情 +