我们只做高品质的产品

公司以诚信、实力和产品质量获得业界的认可,欢迎各界朋友莅临参观,指导和业务洽谈

-

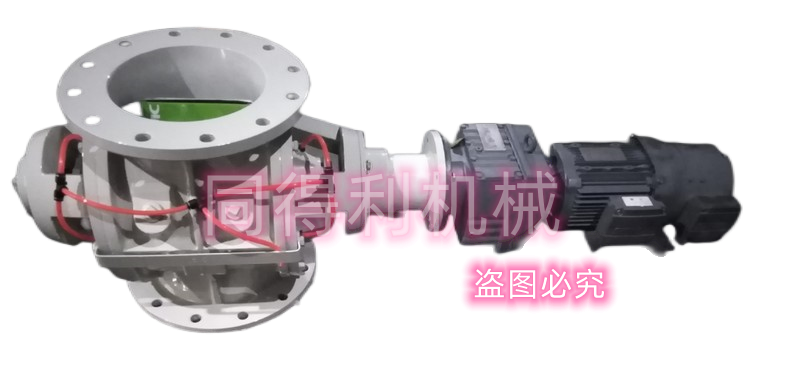

耐压阀 正负压输送卸料阀/

-

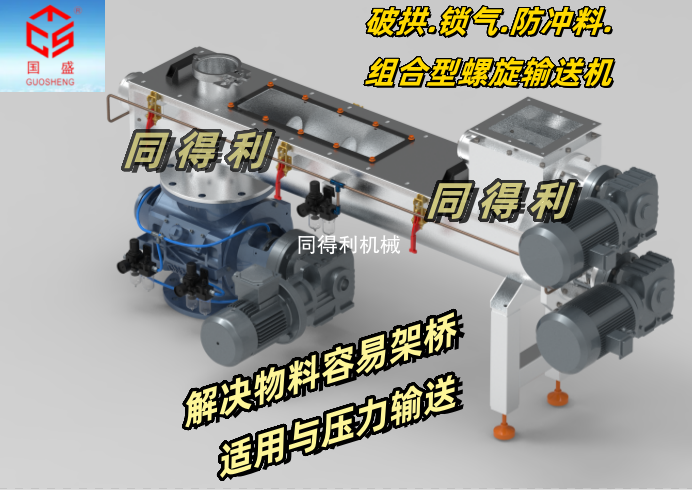

【国产 VS 进口】螺旋输送机-蛟龙上料机/ 绞龙螺旋输送机,螺旋上料机,螺旋输送机,螺杆输送机,螺杆上料机

产品介绍螺旋输送机/绞龙输送机/螺杆上料机专为塑料及粉体生产加工行业设计制造,本机与物料接触部分全部采用不锈钢制作,可与各种规格挤出机,高速混合机,塑料搅拌机配套使用,广泛适用于各类粉状,粒状,回收破碎等物料的上(送)料用途。 可多机串联使用,具有:自动控制加料,维修方便,安全可靠,提高工作效率等优点。接触物料采用不锈钢制作,输送过程中原料完全不受污染,不带入任何异物,能使生产过程中实现封闭自动化。 The screw conveyor/auger conveyor/screw feeder is designed and manufactured specifically for the plastic and powder production and processing industry. The parts in contact with the materials are all made of stainless steel and can be used in conjunction with various specifications of extruders, high-speed mixers, and plastic mixers. It is widely used for feeding various types of powder, granular, recycled and crushed materials. It can be used in series with multiple machines and has the advantages of automatic feeding control, convenient maintenance, safety and reliability, and improved work efficiency. The contact material is made of stainless steel, and the raw materials are completely uncontaminated during the transportation process, without bringing in any foreign objects, which can achieve closed automation in the production process.【电话/微信咨询:陈经理18068546632】 【螺旋输送机类型】: 1、破拱.锁气.防冲料.组合螺旋送料机; 2、双向螺旋输送机; 3、精准喂料螺旋送料机; 4、子母螺旋输送机 / 双轴; 5、提升螺旋输送 / 垂直; 6、双螺旋输送机; 7、滑杆快拆螺旋送料机; 8、高温螺旋输送机; 9、水冷式螺旋输送机 ≥1000℃ 。 Spiral conveyor type: arch breaking Lock the air Anti erosion material Combination spiral feeder; Bidirectional screw conveyor; Precision feeding screw feeder; Mother child screw conveyor; Enhance spiral conveying; Double helix conveyor; Sliding rod quick disassembly spiral feeder; High temperature screw conveyor. 【主要材质】:不锈钢食品抛光304.316.310.等.钛合金.喷涂陶瓷.碳化钨.四氟.陶瓷.尼龙.碳钢.定制. (总有一款适合您的需求)【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询螺旋输送机》 Main materials: stainless steel food polishing 304.316.310. etc Titanium alloy Spray painted ceramics Tungsten carbide Tetrafluoroethylene Ceramics Nylon Carbon steel. 【电话/微信咨询:陈经理18068546632】 【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询螺旋输送机》 《扫二维码-添加 陈经理 微信-咨询绞龙螺旋输送机》查看详情 +

-

【链驱动】正压输送旋转阀-粉体/ 粉体旋转阀,粉料旋转阀,正压旋转阀,气力输送旋转阀

产品介绍正压稀相气力输送系统是采用罗茨风机或者罗茨空压泵作为动力源。利用空气动能作为输送介质,物料以比较高的速度并以分散悬浮的状态在管道中输送。输送的压力一般根据工况条件不同可在几千帕到几百千帕范围内调整。 利用气体动压,物料以较高速度在输送管道中前进(8m/s-25m/s ),输送压力沿输送管道逐渐降低; 连续输送,输送流态、输送压力与输送速度、料气比基本保持稳定; 在一定情况下,输送距离较正压密相短、较负压稀相长; 输送过程中,罗茨鼓风机的出口空气温度较高; 为了防止串气,系统需要配备密闭性较好的旋转供料阀/旋转阀/星型卸料阀/关风机卸料器。【电话/微信咨询:陈经理18068546632】 正压输送旋转阀/风送式旋转阀主要用于化工、食品、药材、锂电、塑料原料输送。 针对物料粘接,风力直吹转子清理物料。 主要材质:不锈钢304-316、钛合金、铝合金、各种合金。 《扫二维码-添加 陈经理 微信-咨询链驱动正压旋转阀》 The positive pressure dilute phase pneumatic conveying system uses Roots blower or Roots air pump as the power source. Using air kinetic energy as a conveying medium, materials are transported in pipelines at relatively high speeds and in a dispersed and suspended state. The conveying pressure can generally be adjusted within the range of several thousand pascals to several hundred kilopascals according to different working conditions. Using gas dynamic pressure, the material advances at a high speed in the conveying pipeline (8m/s-25m/s), and the conveying pressure gradually decreases along the conveying pipeline; Continuous conveying, the conveying flow state, conveying pressure and speed, and material gas ratio remain basically stable; In certain circumstances, the conveying distance is shorter than that of the positive pressure dense phase and longer than that of the negative pressure dilute phase; During the conveying process, the outlet air temperature of the Roots blower is relatively high; In order to prevent air leakage, the system needs to be equipped with a well sealed rotary feeding valve/rotary valve/star shaped discharge valve/shut-off fan discharge device. Positive pressure conveying rotary valve/pneumatic rotary valve is mainly used for conveying chemical, food, medicinal materials, lithium batteries, and plastic raw materials.查看详情 +

-

【防卡型】DN300偏置式旋转阀/ 偏置卸料阀,DN300旋转阀,偏置星型卸料器,偏置式旋转阀

产品介绍防卡型旋转阀主要用于颗粒料、块状料、片状料和重力下料和气力输送卸料,配备特殊防卡结构的导流槽。一般采用V型进料口,叶片顶端倒角;一体式阀体排气口。 法兰形式:圆形、方形、偏置式。 偏置式旋转阀主要用于钢厂、电厂、水泥、矿山原料输送。适用于块状、颗料、片状物料,起到很好的防卡防堵作用。【电话/微信咨询:陈经理18068546632】 1.适用于≤4kg/cm2系统压力或压差。 2.设置排气口(正压输送时选用)将叶轮旋转带出的高压气体通过排气口送至排气装置,提高填充效率。 3.防切料入口设计,即便上游充满物料也可安全启动。 4.轴承外置式安装、经久耐用、性能优异。 5.提供链驱动、直联驱动多种安装方式。 6.根据需求配置减速机电机。 7.材质主要有:不锈钢304-310系列、铝合金、钛合金等。【电话/微信咨询:陈经理18068546632】 我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于锂电池、粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、塑料、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及管网正负压状态下的卸料。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询偏置式旋转阀》 Anti jamming rotary valves are mainly used for granular materials, block materials, sheet materials, gravity feeding, and pneumatic conveying unloading, equipped with special anti jamming structure guide grooves. Generally, a V-shaped feed inlet is used with chamfered blade tips; Integrated valve body exhaust port. Flange forms: circular, square, offset. Offset rotary valves are mainly used for conveying raw materials in steel mills, power plants, cement, and mines. Suitable for block, particle, and sheet materials, it has a good anti jamming and anti blocking effect. 1. Suitable for system pressures or pressure differentials of ≤ 4kg/cm2. 2. Set up an exhaust port (selected for positive pressure conveying) to send the high-pressure gas carried out by the impeller rotation to the exhaust device through the exhaust port, improving the filling efficiency. 3. Anti cutting material inlet design, even if the upstream is filled with materials, it can be safely started. 4. The bearing is externally installed, durable, and has excellent performance. 5. Provide multiple installation methods for chain drive and direct drive. 6. Configure the gearbox motor according to the requirements. 7. The main materials include stainless steel 304-310 series, aluminum alloy, titanium alloy, etc. Our company specializes in the production of (B) GFY, YJD series air shut-off fans (air shut-off devices), star shaped unloaders, DS series electric air locks, DN type rotary valves, quick opening valves, cleaning valves, pneumatic rotary valves and other products. Widely used in equipment for industries such as lithium batteries, grain, feed, petrochemicals, pharmaceuticals, starch, oils and fats, chemical drying, plastics, dust removal, metallurgy, environmental protection, electronics, coal, construction, and power machinery. Used for unloading solid granules, powders, and ultrafine powders under pneumatic conveying and positive and negative pressure in pipeline networks.查看详情 +

-

【密封锁气】防卡式卸料阀-不卡料|不堵料/ 锁气卸料阀,密封卸料阀,防卡式卸料阀,防卡旋转阀,防卡星型卸料器

产品介绍卸料阀又称卸料器、星型卸料阀、旋转阀、旋转卸料阀、旋转给料器、关风机、关风器、锁气阀、电动锁气器、旋转供料阀,通常星型卸料器的结构是由带有数片叶片的转子叶轮、壳体、密封件及减速器、电动机等组成。 Unloading valve, also known as unloader, star shaped unloading valve, rotary valve, rotary unloading valve, rotary feeder, shut-off fan, shut-off fan, air lock valve, electric air lock, rotary feeding valve, is usually composed of a rotor impeller with several blades, a housing, seals, a reducer, an electric motor, etc. Z(B)FK防卡式卸料阀系列: 压力:2kg/cm²系统压力或压差。 增大入口/出口:正方形和圆形。 轴承外置式:有效的防止粉尘侵入轴承,增大设备适应较高温度的使用范围。 驱动方式:链驱动/马达直连驱动口。 动力配置:摆线针轮减速机、Y系列电机(可按需方指定动力配置),排气口增压输送时将叶轮旋转带出的高压气体通过排气口送至排气装置,提高填充效率。【电话/微信咨询:陈经理18068546632】 防卡式卸料阀材质选项:碳钢、铸铁、不锈钢、铝合金、钛合金、陶瓷系列等。 气密封卸料阀主要用于在气力输出系统中,特别是在需要处理粉尘和小颗粒物料的场合。气密封卸料阀的工作原理依赖于气体密封技术,通过保持一定的气源压力,通常高于管道内压力0.1个大气压,从而在卸料阀内部形成正负压差,确保充气的压力大于内部物料的压力,从而实现有效的密封。这种设计不仅提高了卸料阀的可靠性,还能有效防止物料在输送过程中的泄漏,确保系统的正常运行。 我公司专 业生产(B)GFY、YJD系列关风机(关风器)、星型卸料器、DS系列电动锁气器、DN型旋转阀,快开阀、清洁阀、风送式旋转阀等产品。广泛应用于锂电池、粮食、饲料、石油化工、制药、淀粉、油脂、化工干燥、塑料、除尘、冶金、环保、电子、煤炭、建筑、电力机械等行业设备上。用于固体粒料、粉料、超微粉体在气力输送及管网正负压状态下的卸料。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询气密封防卡式卸料阀》 Z (B) FK anti card unloading valve series: Pressure: 2kg/cm ² system pressure or pressure difference. Increase entrance/exit: square and circular. External bearing: effectively prevents dust from entering the bearing and increases the equipment's adaptability to higher temperatures. Drive mode: chain drive/motor directly connected to the drive port. Power configuration: Cycloid pinwheel reducer, Y-series motor (can be configured according to the power requirements specified by the demand). When the exhaust port is pressurized and transported, the high-pressure gas carried out by the impeller rotation is sent to the exhaust device through the exhaust port to improve the filling efficiency. Material options for anti card discharge valve: carbon steel, cast iron, stainless steel, aluminum alloy, titanium alloy, ceramic series, etc.查看详情 +

-

【滑杆式】陶瓷旋转阀-防腐耐磨耐高温/ 陶瓷卸料阀,滑杆式旋转阀,滑杆卸料阀,陶瓷旋转阀,清洗型旋转阀

产品介绍滑杆式旋转阀/卸料阀/星型卸料器/旋转给料器主要结构:外壳金属;物料接触部分:内衬陶瓷、尼龙、四氟、特氟龙、钛合金、铝合金、不锈钢。 滑杆式旋转阀主要用于输送锂电池正极材料、磷酸铁锂、三元材料、化工、食品、制药、塑料等。 滑杆式旋转阀特点:物料粘接设备,可以快速清理,快速复位。 稳定性优于其他开拆式阀门,可原地抽出转子。 清洗前的拆卸:松开螺栓手柄,沿导柱将端盖轻轻拉至极限,抽出叶轮,双手握住叶轮两端抽颈取出。清洗后,装入叶轮(转动叶轮使花键齿合),推入端盖(转动活动轴柄使花键齿合),拧紧螺栓手柄。 驱动方式:链驱动/马达直连驱动。 动力配置:摆线针轮减速机,Y系列电机(可按客户指定动力配置)【电话/微信咨询:陈经理18068546632】 内衬陶瓷旋转阀具有平滑的表面和优异的耐腐蚀性,不会吸附有害物质和细菌。可以保持储存和传输介质的洁净,提高生产质量和安全性。陶瓷内衬具有优异的电绝缘性和高硬度,可以提高旋转阀的性能和稳定性,并减少旋转卸料阀的磨损和损坏。陶瓷内衬还可以起到防爆的作用。由于陶瓷内衬具有较高的抗压强度和耐冲击性,它可以有效地抵御爆炸或高压气体产生的冲击和破坏。 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理 18068546632】 《扫二维码-添加 陈经理 微信-咨询滑杆式陶瓷旋转阀》 Sliding rod rotary valve/discharge valve/star shaped unloader/rotary feeder Main structure: metal shell; Material contact parts: lined with ceramic, nylon, PTFE, PTFE, titanium alloy, aluminum alloy, stainless steel. Sliding rod rotary valves are mainly used for transporting lithium battery cathode materials, lithium iron phosphate, ternary materials, chemical, food, pharmaceutical, plastic, etc. Features of sliding rod rotary valve: Material bonding equipment, can be quickly cleaned and reset. Stability is superior to other detachable valves, and the rotor can be pulled out in place. Disassembly before cleaning: Loosen the bolt handle, gently pull the end cover along the guide column to the limit, extract the impeller, and hold both ends of the impeller with both hands to remove the neck. After cleaning, install the impeller (rotate the impeller to engage the spline teeth), push in the end cover (rotate the movable shaft handle to engage the spline teeth), and tighten the bolt handle. Drive mode: chain drive/direct motor drive. Power configuration: Cycloid pinwheel reducer, Y series motor (can be configured according to customer's specified power)查看详情 +

-

【快拆式】星型卸料器-对标进口品牌/ 卸料阀,星型卸料器,快拆是卸料器,快拆卸料阀,清洗型卸料器

产品介绍快速清洗型旋转阀/星型卸料器广泛应用于食品、医药、化工对卫生高要求场合,以及更换物料频繁需要清理卸料的系统。按操作形式可分为滑杆式和快开式,易于快速清理叶腔中粘性物料,安装方便。 快开门式星型卸料器/卸料阀/旋转阀/旋转供料器:松开固定螺栓,打开端盖门,抽出转子,清洗后转子推入壳体内,旋紧定位螺栓。【电话/微信咨询:陈经理 18068546632】 驱动方式:链驱动/马达直连驱动。 动力配置:摆线针轮减速机,Y系列电机(可按客户指定动力配置) 材质:物料接触部分:内衬聚氨酯、尼龙、四氟、陶瓷、特氟龙、钛合金、铝合金、不锈钢。【电话/微信咨询:陈经理 18068546632】 《扫二维码-添加 陈经理 微信-咨询快拆式星型卸料器》 Quick cleaning rotary valves/star shaped unloaders are widely used in food, medicine, chemical industries with high hygiene requirements, as well as systems that require frequent material replacement and discharge cleaning. According to the operating form, it can be divided into sliding rod type and quick opening type, which is easy to quickly clean viscous materials in the blade cavity and easy to install. Quick opening star shaped unloader/discharge valve/rotary valve/rotary feeder: Loosen the fixing bolts, open the end cover door, extract the rotor, clean it, push the rotor into the housing, and tighten the positioning bolts. Drive mode: chain drive/direct motor drive. Power configuration: Cycloid pinwheel reducer, Y series motor (can be configured according to customer's specified power) Material: Material contact parts: lined with polyurethane, nylon, PTFE, ceramic, PTFE, titanium alloy, aluminum alloy, stainless steel.查看详情 +

-

【清洗型】风送滑杆式旋转阀/ 风送式旋转阀,滑杆式旋转阀,清洗型旋转阀,风送滑杆式旋转阀

产品介绍风送滑杆式旋转阀/卸料阀/星型卸料器/旋转给料阀/旋转供料器主要结构:外壳金属;物料接触部分:内衬陶瓷(也可尼龙、四氟、特氟龙等)。 主要用于食品、药材、锂电、化工、塑料原料输送。 特点:针对物料粘接,风力直吹转子清理。快拆清理,快速复位。 风送滑杆式旋转阀主要材料:不锈钢304-316.陶瓷氧化铝,钛合金、铝合金、陶瓷系列、尼龙、四氟、不锈钢等。【电话/微信咨询:陈经理 18068546632】 快速清洗旋转阀制作精致、成功使用德、日技术制造之精华。产品拆装灵活、易于清洗。主要用于化工、制药、食品等行业高卫生标准的物料卸料及经常更换物料的场所工作。 滑杆式旋转阀:清洗前的拆卸。松开活动瑞盖上的螺旋手柄,沿柱将瑞盖和转子一起拉出,松开轴端的螺旋手柄,取出转子。 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粘料、粉料、超微粉体等。【电话/微信咨询:陈经理 18068546632】 《扫二维码-添加 陈经理 微信-咨询风送滑杆式旋转阀》 Wind driven sliding rod rotary valve/discharge valve/star shaped unloader/rotary feeding valve/rotary feeder Main structure: metal shell; Material contact part: lined with ceramic (also nylon, PTFE, PTFE, etc.). Mainly used for conveying food, medicinal materials, lithium batteries, chemicals, and plastic raw materials. Features: Targeting material bonding, wind blown rotor cleaning. Quick disassembly and cleaning, quick reset. The main materials of the air supply sliding rod rotary valve include stainless steel 304-316. ceramic alumina, titanium alloy, aluminum alloy, ceramic series, nylon, PTFE, stainless steel, etc. The rapid cleaning rotary valve is exquisitely made, and successfully uses the essence of German and Japanese technology. The product is flexible in disassembly and easy to clean. Mainly used for unloading materials with high hygiene standards in industries such as chemical, pharmaceutical, and food, as well as working in places where materials are frequently replaced. Sliding rod rotary valve: disassembly before cleaning. Release the spiral handle on the activity cover, pull out the cover and rotor together along the column, release the spiral handle on the shaft end, and remove the rotor. Changzhou Tongdeli Machinery Factory has many years of experience in research and development, production/customization of discharge valve rotary valves, adhering to the principle of quality first and customer first. Our rotary valves are capable of handling various types of particles, flakes, blocks, adhesives, powders, ultrafine powders, etc. in industries such as lithium batteries, steel mills, power plants, cement, mining, environmental protection, plastics, chemical, food, and pharmaceuticals.查看详情 +

-

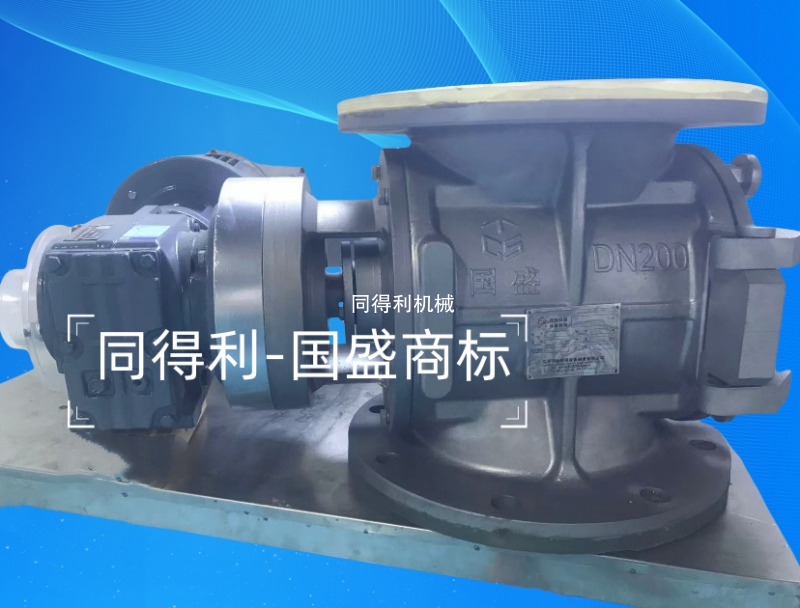

DN200不锈钢快拆清洗型旋转阀/ 清洗型旋转阀,不锈钢旋转阀,快拆式旋转阀,自清洁星型卸料阀,DN200旋转阀

产品介绍侧快拆清洗型旋转阀主要结构:外壳金属;物料接触部分:内衬聚氨酯、尼龙、四氟、陶瓷、特氟龙、钛合金、铝合金、不锈钢。 侧快拆旋转阀主要用于输送锂电池正极材料、磷酸铁锂、三元材料、化工、食品、制药、塑料等。 特点:物料粘接设备,可以快速清理,快速复位。 稳定性优于其他开拆式阀门,可原地抽出转子。【电话/微信咨询:陈经理18068546632】 《扫二维码-添加 陈经理 微信-咨询侧快拆旋转阀》 The main structure of the side quick release cleaning rotary valve is: metal shell; Material contact parts: lined with polyurethane, nylon, PTFE, ceramic, PTFE, titanium alloy, aluminum alloy, stainless steel. The side quick release rotary valve is mainly used for transporting lithium battery positive electrode materials, lithium iron phosphate, ternary materials, chemical, food, pharmaceutical, plastic, etc. Features: Material bonding equipment that can be quickly cleaned and reset. Stability is superior to other detachable valves, and the rotor can be pulled out in place.查看详情 +

-

正负压稀相输送旋转阀-气力输送旋转阀/ 正压旋转阀,负压旋转阀,气力输送旋转阀,稀相输送旋转阀

产品介绍正压稀相输送的介质一般采用空气或氮气,动力提供一般由罗茨鼓风机提供,氮气输送时则有制氮机进行提供。罗茨鼓风机的稀相输送时,物料在管道中呈悬浮状态,输送距离可以达百米,气流速度较高。The medium for positive pressure dilute phase transportation is generally air or nitrogen, and the power supply is usually provided by a Roots blower. When transporting nitrogen, a nitrogen generator is used. During the dilute phase conveying of Roots blower, the material is suspended in the pipeline, with a conveying distance of up to 100 meters and a high airflow velocity. 由于系统处于正压,所以密封性要求很高,若有一丝泄漏就会造成供料端或者整个系统的粉尘外溢;系统物料采用吹送式。Due to the positive pressure of the system, high sealing requirements are required. Any slight leakage can cause dust to overflow from the feeding end or the entire system; The system materials are blown. 风送式旋转阀的工作原理是通过阀芯的旋转来改变物料输送:粉体/颗粒料/粉料/固体料的通道,同时依靠密封机构和驱动装置来保证阀门的密封性能和控制精度。【电话/微信咨询:陈经理18068546632】The working principle of the pneumatic rotary valve is to change the material conveying channels of powder/particle/powder/solid materials through the rotation of the valve core, while relying on the sealing mechanism and driving device to ensure the sealing performance and control accuracy of the valve. 负压稀相输送系统采用负压罗茨泵动力源,管道输送压力呈低真空状态,管道风速约10~35m/秒,物料在管道里呈雾状。负压输送起点压力等于或接近大气压,终点压力在-10至~50Kpa之间,管道真空度沿输送管道逐渐增高。负压稀相输送系统也称为真空稀相输送系统。【电话/微信咨询:陈经理18068546632】The negative pressure dilute phase conveying system adopts a negative pressure Roots pump power source, and the pipeline conveying pressure is in a low vacuum state. The pipeline wind speed is about 10-35m/s, and the material is in a mist state in the pipeline. The starting pressure of negative pressure conveying is equal to or close to atmospheric pressure, and the ending pressure is between -10 and~50Kpa. The vacuum degree of the pipeline gradually increases along the conveying pipeline. The negative pressure dilute phase conveying system is also known as the vacuum dilute phase conveying system. 常州同得利机械厂拥有多年的研发生产/定制卸料阀旋转阀的经验,秉承质量第 一、用户至 上的原则。我们的旋转阀能够处理锂电池、钢厂、电厂、水泥、矿山、环保、塑料、化工、食品和医药等行业的各种颗粒、片状、块状物料、粉料、超微粉体等。【电话/微信咨询:陈经理 18068546632】 我公司是集科研、开发、设计、制造、售后服务于一体的环保型机械重 点企业。公司地处经济发达的长江金三角,坐落在全国闻名的科技示范城-龙城常州,地理位置优越,千年古运河入境而过,沿江高速、京沪高速、沪宁高速纵横交错,交通十分便利。 《扫二维码-添加 陈经理 微信-咨询正负压稀相输送旋转阀-气力输送旋转阀》Changzhou Tongdeli Machinery Factory has many years of experience in research and development, production/customization of discharge valve rotary valves, adhering to the principle of quality first and customer first. Our rotary valves are capable of handling various types of particles, flakes, blocks, powders, ultrafine powders, etc. in industries such as lithium batteries, steel mills, power plants, cement, mining, environmental protection, plastics, chemical, food, and pharmaceuticals.Our company is a key environmentally friendly machinery enterprise that integrates scientific research, development, design, manufacturing, and after-sales service. The company is located in the economically developed Yangtze River Golden Triangle, in the nationally renowned science and technology demonstration city - Longcheng Changzhou, with a superior geographical location. The millennium old canal enters the country, and the Yangtze River Expressway, Beijing Shanghai Expressway, and Shanghai Nanjing Expressway crisscross, making transportation very convenient.查看详情 +